If you have a need to contact us, email us at [email protected] or use the form below.

We look forward to serving you!

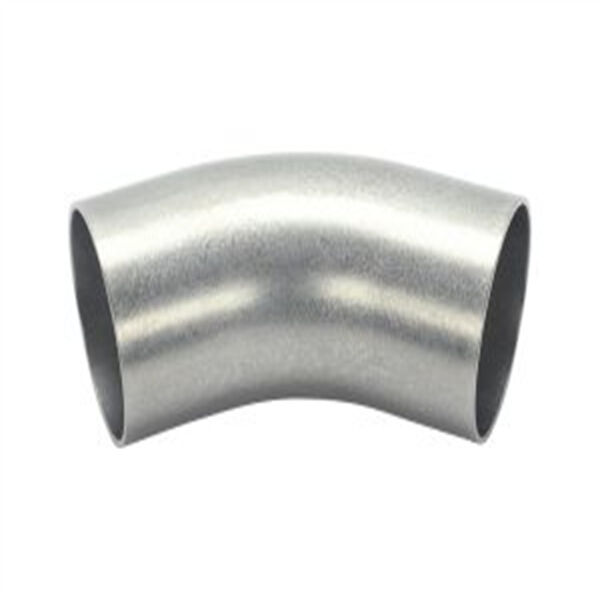

A Fundamental Guide to Weld-On Elbows by TOBO GROUP

You should consider using TOBO GROUP's weld-on elbows if you're buying a trustworthy and efficient option to connect pipelines. These accessories are trusted in several industries, from plumbing to manufacturing. We are going to explore the advantages of weld on elbows, their particular application and how to make usage of all of them safely and effectively.

Weld-on elbows offer several advantages over other styles of pipe connections. Probably one of the most significant benefits is their unique energy. TOBO GROUP's welded elbows are generally stronger than threaded or slip-on contacts, because they count on a material that is definitely a constant which will withstand high heat pressure.

An additional advantage of weldable elbows is their flexibility. They truly are presented in numerous angles and sizes, that enables for lots more creative and work plumbing is adaptable piping designs. Weld-on elbows may be more durable also than other forms of contacts, simply because they lack parts that are movable and can wear on or corrode.

Current improvements in installing technology have permitted even greater innovation within the make and design of TOBO GROUP's weld-on elbows. Several of the newest innovations consist of specialized coatings which could prevent rust and corrosion, also superior alloys that may withstand extreme conditions and pressures. Furthermore, numerous modern weld reducer feature advanced flow control capabilities, which can help optimize system performance and minimize energy waste.

Welding requires ability, equipment, and protection safety precautions to get rid of accidents and make certain that the bones are leak-free and sturdy. When welding elbow 90, it's important to use clothing, defensive helmets, and gloves, and to follow safe welding practices. Inappropriate welding practices can lead to damage which definitely leaks architecturally along with other issues.

When utilizing TOBO GROUP's Weld-On Elbows, it is critical to choose the appropriate angle and dimensions when it comes to application in particular. Make certain you choose a connector which will cope with pressure and tension connected with liquids or gasses moving during your pipes. Find the chemical compatibility of the metals you should be welding together.

Weld on elbows

have provided our company's engineering industry with high-quality metal steel Weld on elbows. With modern production equipment and an extensive quality control, business can ensure the durability reliability its products.

We specialize producing the nickel-based alloys as well as titanium alloy Weld on elbows, including reducers, flanges, Tees, various other thermal products. value importers of steel. Our goal is to help customers find right product and ensuring product quality. vast product line guarantees you will find the best solution your needs regardless of whether you are in manufacturing, construction, oil and gas industry or another industry.

those who are just Weld on elbowsimporters, getting from China can be difficult. TOBO attaches great importance importers, specifically within the steel sector. assist our customers in finding the top manufacturers and ensure quality of their products. We also coordinate delivery to the port. This makes whole purchase process less risky.

Utilizing weld-on elbow is relatively simple, however it does require some knowledge and definitely a technical skill. Firstly, choose the TOBO GROUP's elbow which is definitely an acceptable dimension when it comes to pipelines. Next, clean and prepare the pipe finishes by removing any trace of dirt, rust, or oil. A cable brush or sandpaper enables you to achieve a smooth and clean area.

Then, take advantage of flanges welding devices to join the two pipes together, following the welding which is definitely a standard and security tips. After the joint has cooled off, you can add a sealant or paint to definitely protect the text from deterioration and other environmental harm.

When selecting weld-on elbows, it's definitely important to choose a professional and dependable supplier. Seek out makers having a track proven of high customer service and quality support like TOBO GROUP. A great provider definitely provides detailed technical specifications and testing data, and guarantee information for their elbow steel butt welding products.

Weld-on elbows are used in a broad choice of requests, coming from industrial pipes function towards production industrial. A few of one of the absolute most common uses of TOBO GROUP's weld-on elbow consist of:

1. HVAC techniques: Weld-on elbows are familiar with web link pipes in house home heating, air flow, and air conditioning systems.

2. Supply of water and drain techniques: Weld-on elbow allows you to web link pipes in supply of water as well as drain techniques in residential and structures which are industrial.

3. Oil and fuel pipes: Weld-on elbows are required in the fuel and oil company, where they are actually utilized towards take part pipelines in drilling rigs, pipes, and refineries.

4. Chemical handling blossoms: Weld-on elbows could be utilized in chemical vegetation to contact pipes and bring assertive and destructive items.

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy