If you have a need to contact us, email us at [email protected] or use the form below.

We look forward to serving you!

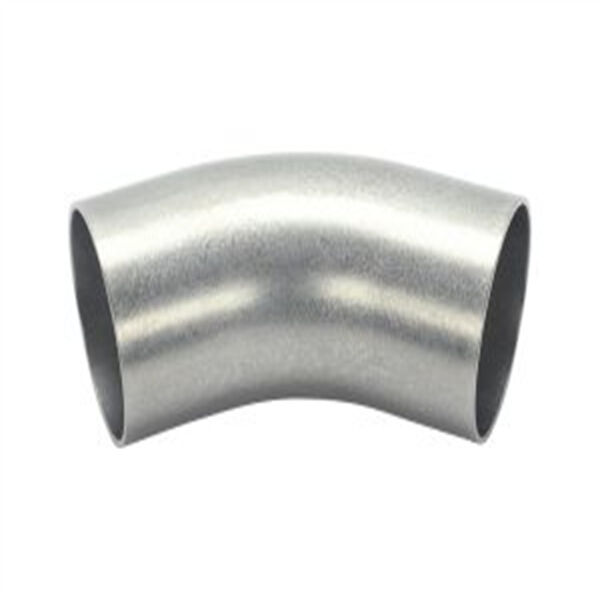

A weld on elbow might sound like a huge word, but this is easy to understand. Consider a pipe that is required to switch direction. Instead of bending the pipe and possibly making it weak you can weld an elbow to two pipes to connect them at an angle. It helps to change the direction of the pipe without losing strength. So, weld on elbows are like buddies that assist in the flow of a piping system for liquids or gases.

Properly welding on elbows is crucial for the safety and efficiency of a piping system. Cleaning the ends of the pipes will remove any dirt or debris. Then you need to put the weld on elbow on the pipes and tack weld them in place. Pass through the hoses, confirming that the elbows are focused before welding them firmly. Lastly, confirm that there are no issues with the welds so that it is a strong connection. The elbow weld itself is like a handshake that keeps the pipes together.

There are a few things to consider when selecting weld on elbows. You will have to make sure that the elbow you select will match the same size as your pipes so that they fit properly. Well, consider the material for the weld on elbow. All materials have different characteristics (e.g. being rust resistant or high-temperature resistant). Ensure you select a suitable material for your piping system. So, as long as you select the correct size and material for your weld on elbows, you can depend on them to performing their functions for a long time.

Weld on elbows– the advantages of using them in piping systems. First, they allow liquids or gases to flow more freely, which can minimize turbulence or pressure fluctuations throughout the system. This will improve the performance of the piping system and save energy. Additionally, welded elbows are powerful and can withstand high temperatures and pressures, so they're awesome for a lot of applications. And they can further simplify and economize installation time and labor. Welding elbows are often considered the unsung heroes of piping systems, ensuring fluid flow is compromised.

While it might seem simple to weld on elbows, there are a few pitfalls to avoid. One big thing is not cleaning the pipes properly before welding, which will render weak connections. Another common mistake would be not having the elbows lined up properly before welding, which would cause the pipes to be mis-aligned. Too much or not enough welding will both lead to a weak connection or leaks. Using proper welding techniques is vital to ensure that the weld is safe and strong. These mistakes can compromise reliable piping systems and lead to safety issues.

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy