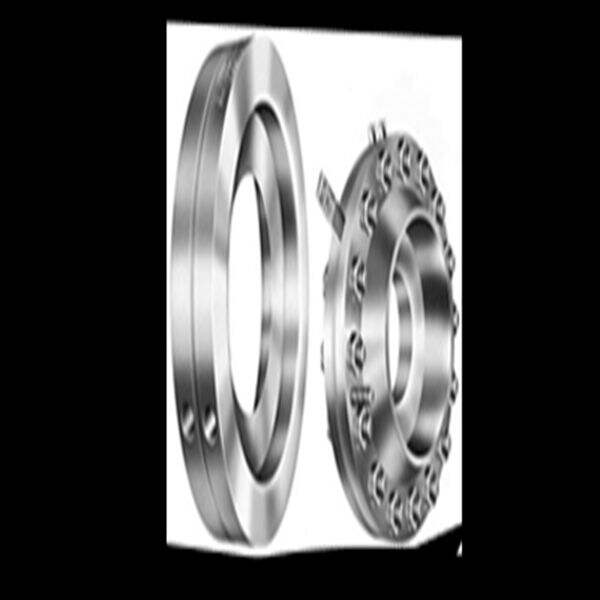

One type is called a duplex flange, and it is used in pipe fittings that are usually found at factories or in large buildings. This flange is a favorite among engineers and plumbers as they have many good features.

Duplex flanges are strong and can resist rust. Two types of stainless steel that have been mixed together. It also makes them stronger than standard flanges. As a result of this, they are resistant to high pressure and heat without breaking or leaking.

Also, duplex flanges are resistant to rust caused by chemicals and water. Regular flange pipes can be damaged by accidental shocks, and it could wear out the piping.

If duplex flanges is correctly installed and maintained, it will perform optimally. Then, when you insert them, follow the instructions carefully to ensure that they fit snuggly. Prevent leaks and other issues just by cleaning the flanges and checking for damage.

Engineers and plumbers can compare duplex flanges with other different flanges to find which ones they should be using to sustain their pipes. Duplex flanges may be more expensive than standard flanges, but their strength and resistance to rust can prove to be much more economical in the long run. Examining the pros and cons of each type of professional can help professionals select the right professional for them.

It is quite essential to select the proper duplex flange. Since different duplex flanges are available for pending applications, you need to find out the right size that suits you best. Examples of things to consider are pressure, heat, and what chemicals will be present at the flange to ensure it passes the test for effective sealing over a long time.

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy