If you have a need to contact us, email us at [email protected] or use the form below.

We look forward to serving you!

Inconel 825 is a special type of high-strength alloy that possesses excellent resistance to corrosion in acidic and alkali environments, making it suitable for various applications. This metal has unique properties that are helpful in various operations. Course preview: Learn more about ASTM B564 N08825 standard and its application.

This standard is used for guidance of Inconel 825 alloy making and testing. This is nickel metal alloy with other elements such as chromium and iron. Has a very high resistance to corrosive environments and high temperature strength. That makes it excellent for operating in harsh environments. The ASTM B564 ensures that the alloy is of excellent quality and performs effectively.

BF0707560: Let me tell you some Key features of Inconel 825 alloy. It has been shown to withstand damaging environments, such as acids, bases, and seawater. It also has some mechanical properties, meaning it can withstand a lot of force and is durable. It can also remain firm in high heat and under rapid temperature changes. Such features make ASTM B564 N08825 a widely used option for applications requiring high performance and safety.

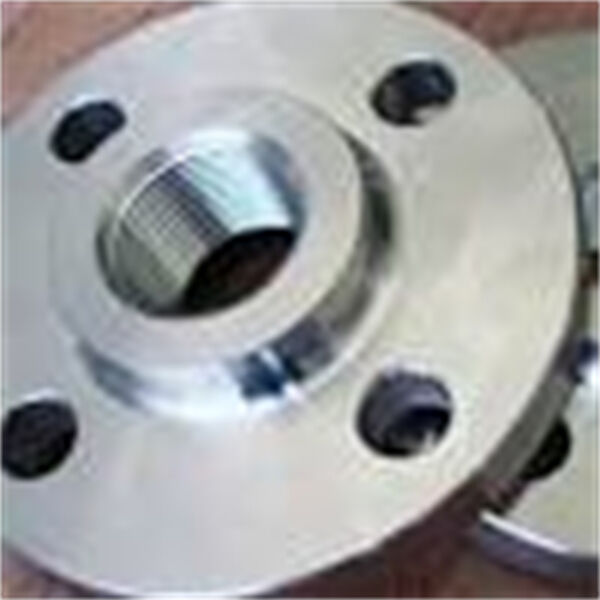

Due to the special properties of ASTM B564 N08825 Alloy, it is used in a variety of industries. It is commonly used in the chemical processing, oil and gas, and maritime sectors. In chemical processing, it’s used on the tanks, valves and pumps that come in contact with deadly chemicals. In oil and gas work, for example, it is used for pipes, fittings and other components that must withstand high pressure and heat. In the marine fields, it is used in pipes, heat exchangers, and other parts in seawater. In summary, ASTM B564 N08825 alloy is considered a safe and durable alloy in adverse conditions.

Several tests and checks are carried out during production to ensure that ASTM B564 N08825 alloy is of excellent quality. This involves examining the chemical composition of the alloy, assessing its resilience and durability, and employing non-destructive testing to detect flaws. In addition, specific size and surface quality requirements must be met for the alloy. Adherence to these testing and quality control procedures ensures that ASTM B564 N08825 alloy performs satisfactorily and is dependable.

Although there are unique features of ASTM B564 N08825 alloy, it should be compared with other nickel alloys available in the market. A common comparison is made to Inconel 625 another widely used nutrient-deficient nickel-based alloy that shows high strength and resistance to corrosion. Inconel 825 has a higher nickel and molybdenum content than Inconel 625, which makes it more resistant to corrosion in particular environments. But due to its high strength, Inconel 625 can withstand more repeated stress than Inconel 825. Which of these alloys is chosen will often depend on the task at hand.

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy