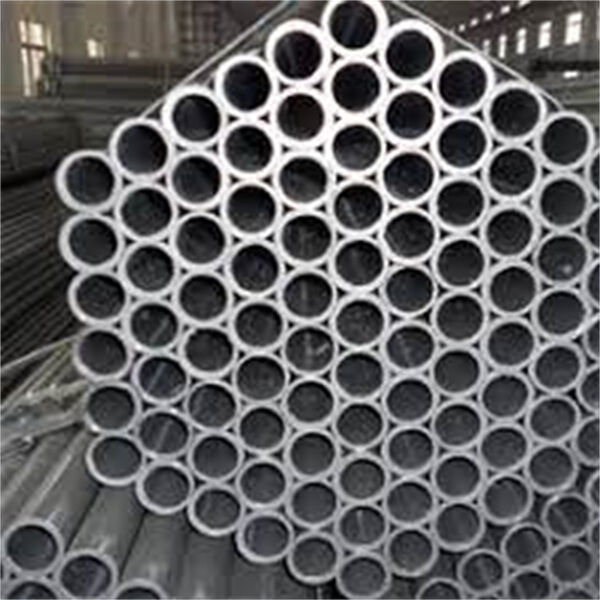

Alloy 690 Tube is a range of Tube that has been a vital part of various industries. It was made of a robust material called alloy 690. It is capable of withstanding temperatures that are quite high, which gives it the ability to work well in harsh conditions where other metals may fail.

The strength of Alloy 690 Tube is one of its most important advantages. Its able to withstand extremely hot temperatures without bending or changing. That makes it great for job sites where things can get really hot. It being strong also means it has longevity and does not have to be replaced as frequently as some of the other materials.

The other benefit of Alloy 690 Tube is that it is not corroded. This helps it last longer, saving time and money. You can use it in various locations without needing to worry about damaging it.

Alloy 690 Tube works well in difficult situations since it is strong and rust-resistant. This includes everything from power plants and chemical factories to outer space. These are extreme environments and Alloy 690 Tube has got your back.

Alloy 690 Tube is successful to several industries as it is durable and strong. Often used in the oil and gas industry for pipelines and heat exchange. It is used in the nuclear industry for reactor parts and fuel rods as well. It is even used in aerospace for jet parts and planes.

How alloy 690 tube is manufactured determines its strength. It is produced by combing various metals to form an extremely durable substance. This means it can absorb a great deal of wear and tear without breaking. It is equally malleable, allowing it to be molded into myriad shapes.

The alloy 690 tube serves to improve the efficiency of various industrial processes. It permits higher temperatures and pressures, enabling more efficient processes, for example. It also lasts longer, so there’s less money and time spent on repairs. In addition, it offers protection because this does not rust or get damaged easily.

Copyright © TOBO GROUP All Rights Reserved - Privacy Policy