Actualités de l'industrie

-

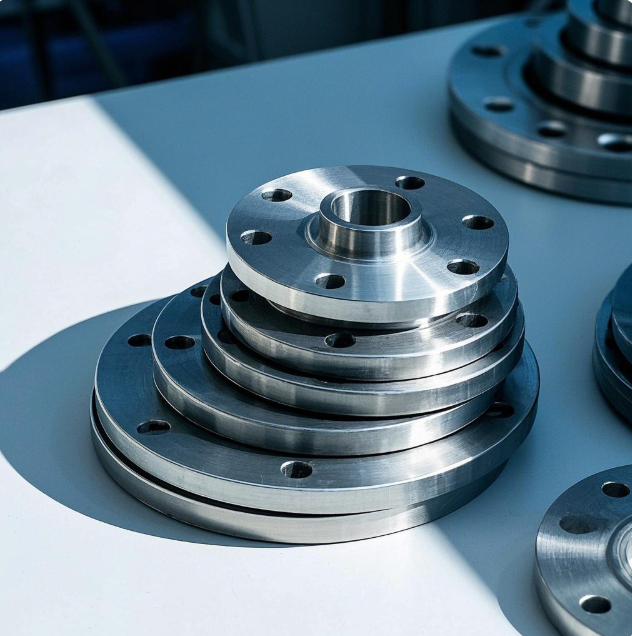

Code ASME B31.3 pour les canalisations industrielles : considérations particulières relatives à la conception avec des compositions d’alliages non standard

2026/02/06Code ASME B31.3 pour les canalisations industrielles : considérations particulières relatives à la conception avec des compositions d’alliages non standard. Comprendre la notion d'« alliage non standard » dans le contexte de la norme B31.3. Dans le cadre de l’ASME B31.3, une « composition d’alliage non standard » désigne généralement un matériau métallique…

-

Se repérer dans le mécanisme européen d’ajustement carbone aux frontières (CBAM) concernant les tubes en alliage haute performance importés

2026/02/05Se repérer dans le mécanisme européen d’ajustement carbone aux frontières (CBAM) concernant les tubes en alliage haute performance importés. Comprendre le CBAM : pourquoi il est essentiel pour les importateurs d’alliages. Le mécanisme européen d’ajustement carbone aux frontières (CBAM) n’est pas simplement une réglementation supplémentaire…

-

La précision du tréfilage à froid : comment celle-ci améliore les propriétés mécaniques des tubes d’instrumentation en alliage de nickel

2026/02/04La précision du tréfilage à froid : comment elle améliore les propriétés mécaniques des tubes d’instrumentation en alliage de nickel. Dans le monde de l’instrumentation de processus critique, des systèmes hydrauliques et des lignes de capteurs, le tube n’est pas simplement une conduite — il s’agit d’un élément précis...

-

La précision du tréfilage à froid : comment celle-ci améliore les propriétés mécaniques des tubes d’instrumentation en alliage de nickel

2026/02/03La précision du tréfilage à froid : comment elle améliore les propriétés mécaniques des tubes d’instrumentation en alliage de nickel. Dans des secteurs exigeants tels que l’aérospatiale, le traitement chimique et la production d’énergie, les tubes d’instrumentation et les tubes capillaires ne sont pas de simples conduits...

-

Acides oxydants contre acides réducteurs : un guide pour les sélectionneurs de matériaux afin de choisir le tuyau résistant à la corrosion adapté

2026/02/02Acides oxydants contre acides réducteurs : un guide pour les sélectionneurs de matériaux afin de choisir le tuyau résistant à la corrosion adapté. Le choix du matériau optimal pour les tuyaux destinés aux services acides constitue l’une des décisions les plus critiques dans la conception et la maintenance des installations chimiques. La...

-

Le défi de la corrosion sous contrainte dans les échangeurs thermiques compacts : sélection des matériaux pour les unités à plaques et cadre

2026/01/30Le défi de la corrosion sous contrainte dans les échangeurs de chaleur compacts : sélection des matériaux pour les unités à plaques et cadre. Les échangeurs de chaleur à plaques et cadre (ECP) sont des modèles d’efficacité, offrant un transfert de chaleur exceptionnel dans un encombrement réduit. Toutefois, leur conception même...

-

Gestion d’une installation comportant des métaux hétérogènes : bonnes pratiques pour les systèmes utilisant de l’acier au carbone, des aciers inoxydables duplex et des alliages de nickel

2026/01/29Gestion d’une installation comportant des métaux hétérogènes : bonnes pratiques pour les systèmes utilisant de l’acier au carbone, des aciers inoxydables duplex et des alliages de nickel. Exploiter une installation combinant de l’acier au carbone, des aciers inoxydables duplex (p. ex. 2205, 2507) et des alliages de nickel (p. ex. alliage 825, C276) est une situation courante...

-

Évaluation de l’aptitude au service (EAS) : à quel moment pouvez-vous continuer à utiliser en toute sécurité une canalisation en alliage 825 présentant une épaisseur réduite ?

2026/01/28Évaluation de l’aptitude au service (EAS) : à quel moment pouvez-vous continuer à utiliser en toute sécurité une canalisation en alliage 825 présentant une épaisseur réduite ? La découverte d’un amincissement inattendu de la paroi sur une section de canalisation en alliage 825 peut déclencher une alerte immédiate. L’arrêt d’urgence et le remplacement semblent alors la seule option sûre...

-

Maintenance prédictive pour les canalisations en acier à haute teneur en alliages : utilisation des données pour planifier les inspections avant les pannes

2026/01/27Maintenance prédictive pour les canalisations en acier à haute teneur en alliages : utilisation des données pour planifier les inspections avant les pannes Pour les responsables d’usine, les ingénieurs en maintenance et les chefs d’exploitation des secteurs de la transformation chimique, de la production d’énergie et de l’exploration pétrolière et gazière offshore, les pannes imprévues…

-

Création d’un jumeau numérique de votre réseau de canalisations résistantes à la corrosion pour une excellence opérationnelle

2026/01/26Création d’un jumeau numérique de votre réseau de canalisations résistantes à la corrosion pour une excellence opérationnelle Depuis des décennies, la gestion d’un réseau de canalisations en alliage résistant à la corrosion (CRA) — véritable système vasculaire de vos unités de procédé les plus critiques — s’est fondée sur une approche réactive…

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

VI

VI

TH

TH

TR

TR

GA

GA

CY

CY

BE

BE

IS

IS